The Ultimate Guide to Machine Label Applicators

Machine label applicators are revolutionary devices that have transformed the way businesses approach labeling. Whether you're in the printing services, electronics, or computers industry, the benefits of integrating a machine label applicator into your production line are immense. This article explores the intricacies of machine label applicators, their benefits, various types, and how they can significantly enhance your business operations.

What is a Machine Label Applicator?

A machine label applicator is a device designed to automate the process of applying labels to various products, ensuring consistency, speed, and accuracy. These machines can handle a myriad of labeling tasks across diverse industries, including packaging, manufacturing, and distribution.

Why Your Business Needs a Machine Label Applicator

- Increased Efficiency: Automating the labeling process drastically reduces the time required compared to manual labeling.

- Precision and Accuracy: Machine label applicators ensure that labels are applied accurately, minimizing errors that can occur with manual processes.

- Cost-Effective: Over time, the initial investment in a machine label applicator can lead to significant savings in labor costs and material wastage.

- Versatility: These machines can be tailored to apply different types of labels, from stickers to barcode labels, suitable for various products.

The Evolution of Labeling Technology

The history of labeling technology is a fascinating journey marked by innovation. Initially, labeling was done manually, a tedious process that took time and required significant manpower. With the advancement of technology, the introduction of machine label applicators brought a remarkable shift. Today's machines are equipped with advanced features, including:

- Smart Technology: Many modern machine label applicators can integrate with inventory management systems for real-time tracking.

- Adjustable Speeds: Adaptability to various production speeds makes labeling seamless.

- High-Quality Printing: Advanced printing capabilities ensure crisp and clear outputs, enhancing product presentation.

Types of Machine Label Applicators

Understanding the different types of machine label applicators is crucial for making the right choice for your business. Here are the most common types:

1. Manual Label Applicators

These are semi-automatic methods allowing operators to apply labels quickly. While not entirely automated, they enhance efficiency compared to manual application alone.

2. Automatic Label Applicators

Fully automated systems designed for high-speed production environments. They can apply labels continuously without human intervention, making them ideal for large-scale operations.

3. Print & Apply Labelers

These combine printing and application processes into one seamless operation. They are perfect for businesses that require on-demand labeling capabilities.

4. Tamp Label Applicators

These applicators use a tamping mechanism to press the label onto the product, ensuring precise placement, especially on uneven surfaces.

5. Wrap-Around Labelers

Designed for cylindrical products, these machines can apply labels around the entire circumference, perfect for bottles and jars.

Benefits of Using a Machine Label Applicator in Your Business

Investing in a machine label applicator can yield numerous benefits. Here are some critical advantages:

1. Time Savings

Manual labeling processes can consume valuable time. Machine label applicators can dramatically cut the time required for labeling, allowing employees to focus on more critical tasks, ultimately enhancing productivity.

2. Enhanced Product Presentation

Consistency in labeling becomes a hallmark of brand identity. With machine label applicators, every label is applied uniformly, presenting your products in a professional manner that attracts consumers.

3. Reduced Labor Costs

By automating the labeling process, you decrease the workforce needed for labeling tasks. The reduction in labor hours translates to significant cost savings.

4. Improved Compliance and Traceability

In industries with stringent regulations, accurate labeling is vital. Machine label applicators ensure that every product is properly labeled, aiding in compliance and traceability throughout the supply chain.

How to Choose the Right Machine Label Applicator

Choosing the right machine label applicator for your business requires careful consideration of several factors:

- Label Size and Shape: Ensure the applicator can handle the dimensions of your labels.

- Production Speed: Assess your production speed requirements and select a model that can meet those demands.

- Type of Products: Consider your product types; some machines are better suited for flat items, while others work well with cylindrical designs.

- Integration with Existing Systems: Look for machines that can easily integrate with your current production and inventory systems.

- Budget: Finally, set a budget and weigh the cost against the potential operational improvements.

Common Applications of Machine Label Applicators

Machine label applicators serve a vast array of industries and applications:

Food and Beverage

In the food and beverage industry, accurate labeling is crucial for compliance with health regulations. Machine label applicators can efficiently label everything from cans and bottles to boxes and bags.

Pharmaceuticals and Health Products

In the pharmaceutical sector, machine label applicators help ensure compliance with strict regulatory standards, providing clear and accurate information that is vital for consumer safety.

Electronics

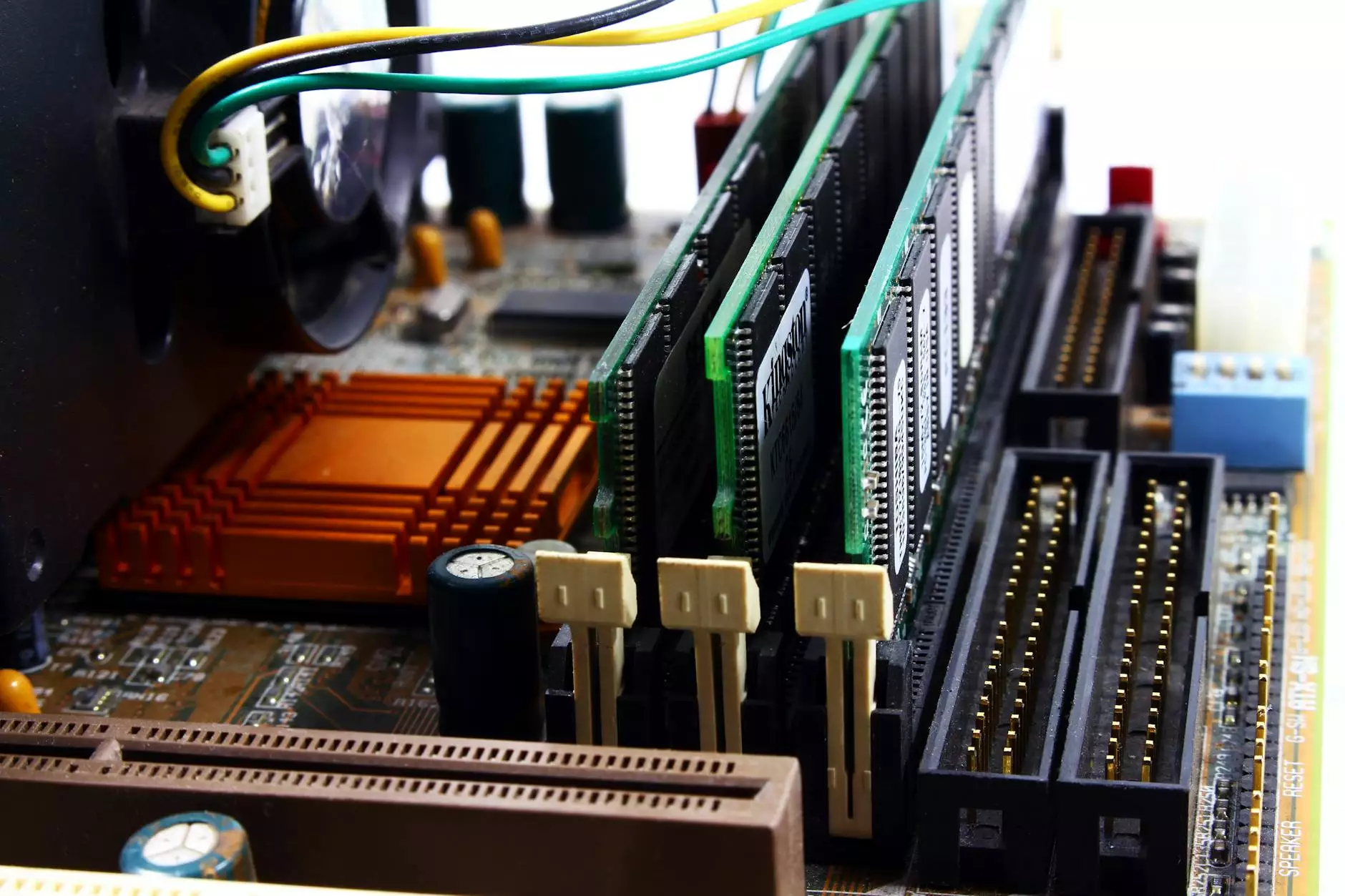

The electronics industry often uses machine label applicators for devices, boxes, and peripheral equipment to maintain brand integrity and convey crucial product information.

Cosmetics and Personal Care

In the increasingly competitive cosmetics market, machine label applicators can enhance the aesthetic appeal of products while supporting high-speed production lines.

Maintenance and Care for Machine Label Applicators

While machine label applicators are built to last, regular maintenance ensures optimal performance. Here are some tips:

- Regular Cleaning: Clean the applicator to prevent residue buildup, which can cause malfunctions.

- Calibration: Periodically calibrate the machine to maintain accuracy in label placement.

- Parts Inspection: Regularly inspect rollers, sensors, and other critical components for wear and tear.

- Manufacturer Guidelines: Always follow the manufacturer's maintenance guide for optimal performance.

Conclusion

The implementation of a machine label applicator can significantly enhance your operational efficiency, accuracy, and overall productivity. With the diverse offerings available through businesses like Omega Brand, there's no better time to integrate this technology into your workflow. By considering the various types and benefits of machine label applicators, along with choosing the right one for your specific needs, you can ensure that your labeling process becomes an asset rather than a bottleneck.

Your journey towards streamlined operations and advanced labeling effectiveness begins today. Embrace the revolution of machine label applicators and watch as your business thrives.